Unveiling the 6000 Series Aluminum Crystal Structure

The 6000 series aluminum alloy is a cornerstone in modern engineering, prized for its versatility, strength, and corrosion resistance. Understanding its crystal structure is key to unlocking its full potential in applications ranging from aerospace to consumer electronics. This post delves into the intricacies of the 6000 series aluminum crystal structure, offering insights for both informational and commercial audiences.

Understanding the 6000 Series Aluminum Crystal Structure

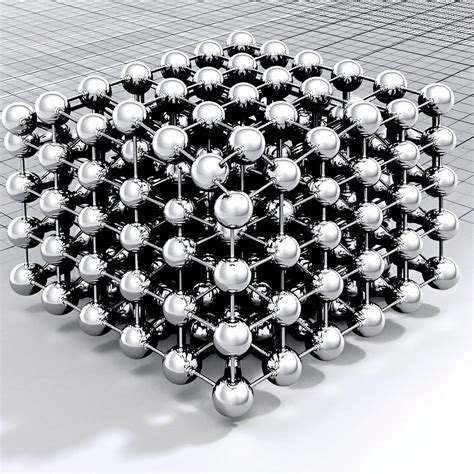

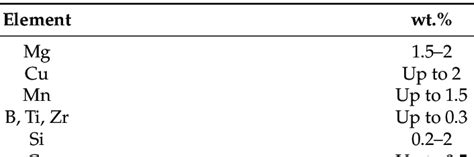

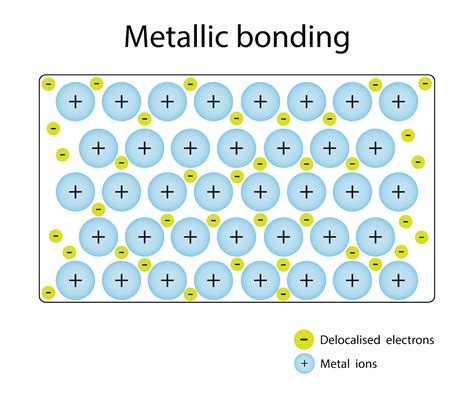

The 6000 series aluminum is primarily composed of aluminum, magnesium, and silicon, with the crystal structure based on a face-centered cubic (FCC) lattice. This structure is responsible for the alloy’s excellent formability and weldability.

Key Components of the Crystal Structure

- Aluminum (Al): Forms the base of the FCC lattice.

- Magnesium (Mg) and Silicon (Si): Act as alloying elements, forming Mg₂Si precipitates that enhance strength.

- Grain Boundaries: Influence mechanical properties like ductility and fatigue resistance.

📌 Note: The Mg₂Si precipitates are critical for the alloy’s age-hardening capabilities.

How the Crystal Structure Influences Properties

The FCC lattice provides inherent ductility, while the distribution of Mg₂Si precipitates determines the alloy’s strength. Heat treatment processes like T6 tempering optimize these precipitates for maximum performance.

Applications of 6000 Series Aluminum

Industrial Uses

- Aerospace: Lightweight components for aircraft structures.

- Automotive: Body panels, chassis, and heat exchangers.

- Construction: Window frames, doors, and roofing.

Commercial Products

- Consumer Electronics: Smartphone casings and laptop frames.

- Sporting Goods: Bicycle frames and hiking gear.

| Application | Key Benefit |

|---|---|

| Aerospace | Lightweight & High Strength |

| Automotive | Corrosion Resistance & Formability |

Heat Treatment and Crystal Structure Optimization

Heat treatment processes like solutionizing and aging refine the crystal structure, enhancing mechanical properties. The T6 temper, for instance, involves:

1. Solutionizing: Dissolving Mg₂Si into the aluminum matrix.

2. Aging: Precipitating Mg₂Si for increased strength.

📌 Note: Over-aging can lead to reduced ductility, so precise control is essential.

Advantages and Limitations

Advantages

- Lightweight: Ideal for weight-sensitive applications.

- Corrosion Resistance: Natural oxide layer protects against corrosion.

- Formability: Easy to shape and weld.

Limitations

- Lower Strength: Compared to 7000 series alloys.

- Temperature Sensitivity: Performance degrades at high temperatures.

Final Thoughts

The 6000 series aluminum crystal structure is a marvel of material science, balancing strength, formability, and corrosion resistance. Whether for industrial or commercial applications, understanding its structure is crucial for optimizing performance.

What is the crystal structure of 6000 series aluminum?

+The 6000 series aluminum has a face-centered cubic (FCC) crystal structure with Mg₂Si precipitates enhancing its strength.

How does heat treatment affect the 6000 series aluminum?

+Heat treatment optimizes the distribution of Mg₂Si precipitates, improving strength and hardness while maintaining ductility.

What are the main applications of 6000 series aluminum?

+It is widely used in aerospace, automotive, construction, consumer electronics, and sporting goods due to its lightweight and corrosion-resistant properties.

aluminum alloys,material science,crystal structure,engineering materials,6000 series aluminum,aluminum applications,aluminum properties,heat treatment,aluminum manufacturing.