Cantilever Beam Airfoil: Design and Applications Explained

Opening Paragraph

Cantilever beam airfoils are a fascinating intersection of aerodynamics and structural engineering, offering unique advantages in various applications. These designs, characterized by their fixed end and free tip, are widely used in aerospace, automotive, and renewable energy sectors. Understanding their design principles and applications can unlock innovative solutions for engineers and designers alike. Whether you’re exploring cantilever beam airfoil design for informational purposes or seeking cantilever beam airfoil applications for commercial projects, this post provides a comprehensive overview.

What is a Cantilever Beam Airfoil?

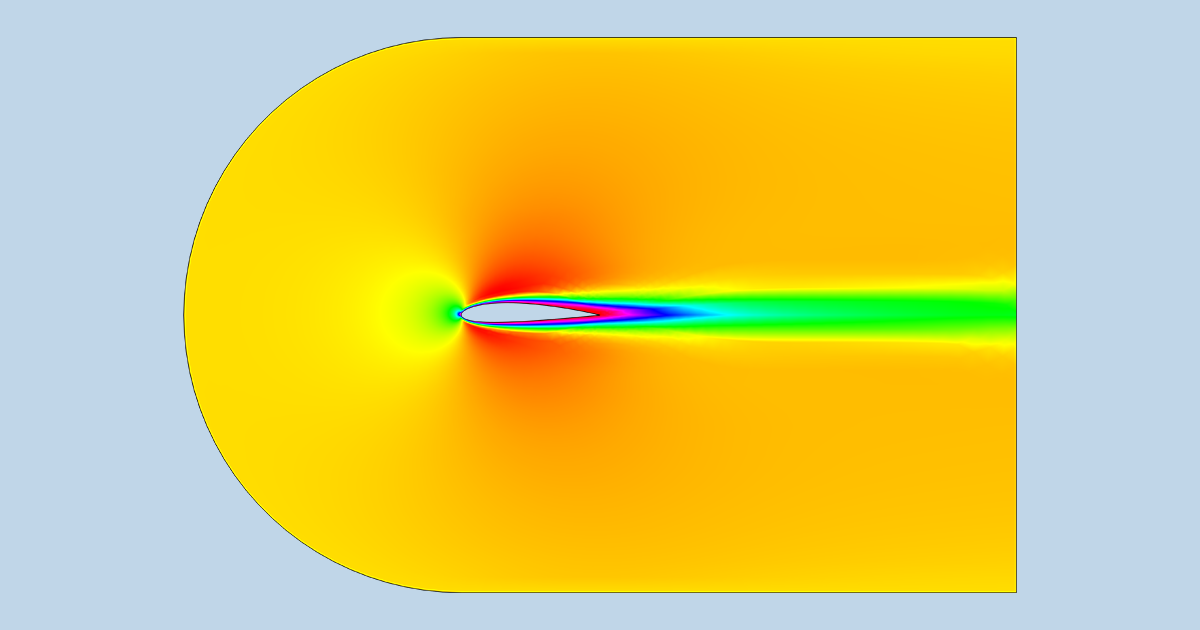

A cantilever beam airfoil is a specialized structure where an airfoil shape is integrated into a beam that is fixed at one end and free at the other. This design maximizes lift and minimizes drag, making it ideal for applications requiring efficient airflow management. The aerodynamics of cantilever beam airfoils are crucial in their performance, ensuring stability and reduced turbulence.

💡 Note: Cantilever beam airfoils differ from traditional airfoils due to their fixed-free structure, which impacts their load-bearing capabilities and aerodynamic efficiency.

Key Design Principles of Cantilever Beam Airfoils

Designing a cantilever beam airfoil involves balancing aerodynamic efficiency with structural integrity. Here are the core principles:

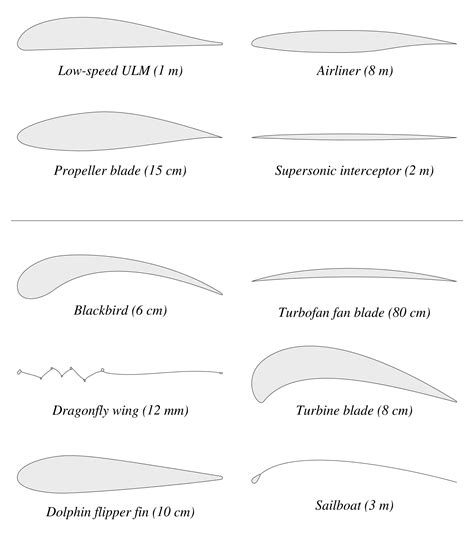

1. Airfoil Shape Optimization

The airfoil profile is critical for achieving desired lift and drag characteristics. Common shapes include NACA series airfoils, tailored for specific applications like wind turbine blades or aircraft wings.

2. Material Selection

Materials like aluminum, carbon fiber, and composites are chosen for their strength-to-weight ratio, ensuring durability under varying loads.

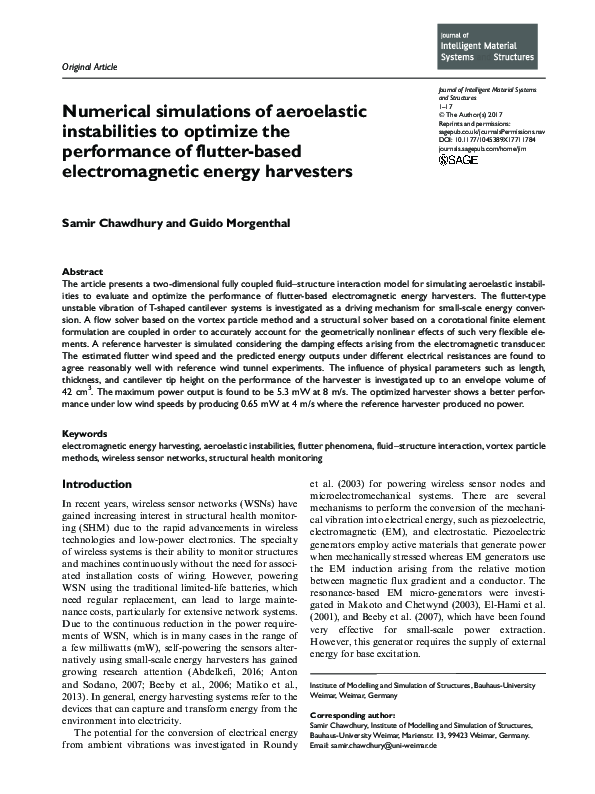

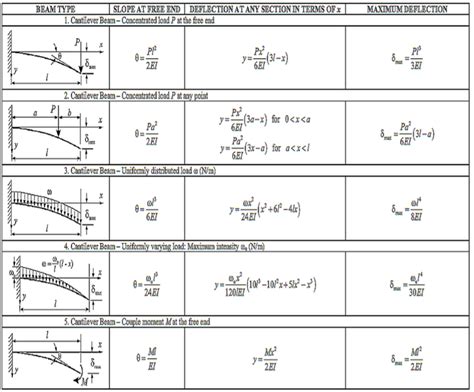

3. Stress Analysis

Cantilever beams experience bending and shear stresses, requiring careful analysis to prevent failure. FEA (Finite Element Analysis) is often used for this purpose.

| Design Factor | Importance |

|---|---|

| Airfoil Profile | Determines lift and drag efficiency |

| Material Strength | Ensures structural integrity |

| Stress Distribution | Prevents failure under load |

Applications of Cantilever Beam Airfoils

Cantilever beam airfoils are versatile, finding use in multiple industries:

- Aerospace: Wing design for aircraft, drones, and spacecraft.

- Renewable Energy: Wind turbine blades for efficient energy conversion.

- Automotive: Spoilers and aerodynamic components for vehicles.

- Civil Engineering: Bridge designs incorporating aerodynamic principles.

For commercial applications, cantilever beam airfoils are often customized to meet specific performance requirements, such as high lift-to-drag ratios or lightweight construction.

Steps to Design a Cantilever Beam Airfoil

- Define Requirements: Determine the application, load conditions, and performance goals.

- Select Airfoil Profile: Choose a suitable airfoil shape based on aerodynamic needs.

- Perform Stress Analysis: Use FEA tools to evaluate structural integrity.

- Optimize Design: Refine the design for weight, cost, and efficiency.

- Prototype and Test: Build a prototype and conduct real-world testing.

✨ Note: Prototyping is essential to validate design assumptions and ensure performance meets expectations.

Checklist for Cantilever Beam Airfoil Design

- [ ] Define application-specific requirements.

- [ ] Select an optimal airfoil profile.

- [ ] Conduct stress and aerodynamic analysis.

- [ ] Choose appropriate materials.

- [ ] Test prototypes under real-world conditions.

Final Thoughts

Cantilever beam airfoils represent a blend of aerodynamics and structural engineering, offering solutions for diverse industries. By understanding their design principles and applications, engineers can harness their potential for innovative projects. Whether for aerospace innovations, renewable energy solutions, or automotive advancements, cantilever beam airfoils continue to shape the future of technology.

What is a cantilever beam airfoil?

+A cantilever beam airfoil is a structure with an airfoil shape fixed at one end and free at the other, designed for efficient airflow management.

Where are cantilever beam airfoils used?

+They are used in aerospace, renewable energy, automotive, and civil engineering applications.

How do you design a cantilever beam airfoil?

+Design involves selecting an airfoil profile, performing stress analysis, optimizing materials, and prototyping for testing.

cantilever beam airfoil design,cantilever beam airfoil applications,aerodynamics of cantilever beam airfoils,wind turbine blades,aircraft wings