Predicting Corrosion Time-to-Failure: Accurate Models for Better Maintenance

Corrosion is a silent threat to infrastructure, machinery, and assets across industries. Predicting corrosion time-to-failure accurately can save businesses millions by optimizing maintenance schedules and preventing unexpected downtime. With advancements in technology, accurate models now enable better decision-making, ensuring longevity and safety. Whether you're managing oil rigs, bridges, or pipelines, understanding these models is crucial. Let’s explore how predictive analytics can transform your maintenance strategy, ensuring efficiency and cost-effectiveness. (corrosion prediction, maintenance optimization, asset longevity)

Understanding Corrosion Time-to-Failure: Why It Matters

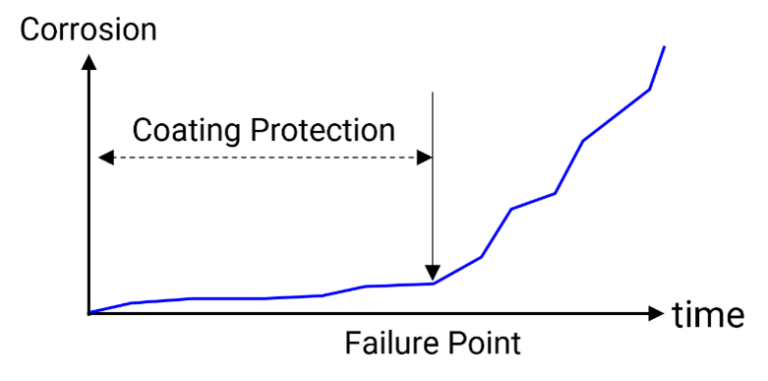

Corrosion time-to-failure refers to the period before a material or structure succumbs to corrosion-induced degradation. Accurate prediction of this timeline is vital for industries like oil and gas, manufacturing, and construction. By identifying potential failures early, companies can schedule proactive maintenance, reduce repair costs, and enhance safety. (corrosion prevention, predictive maintenance, industrial safety)

Key Factors Influencing Corrosion

Several factors contribute to corrosion rates, including environmental conditions, material properties, and operational stress. Understanding these variables is essential for building accurate predictive models:

- Environmental Factors: Humidity, temperature, and chemical exposure.

- Material Composition: Type of metal or alloy used.

- Operational Stress: Load, pressure, and vibration.

(corrosion factors, material science, environmental impact)

Advanced Models for Predicting Corrosion

Modern predictive models leverage data analytics, machine learning, and IoT sensors to forecast corrosion time-to-failure with high accuracy. These models analyze historical data and real-time inputs to provide actionable insights. Popular techniques include:

| Model Type | Key Features |

|---|---|

| Machine Learning | Pattern recognition, adaptive learning |

| Finite Element Analysis (FEA) | Structural stress simulation |

| IoT-Based Monitoring | Real-time data collection |

(machine learning, IoT sensors, corrosion analytics)

Benefits of Accurate Corrosion Prediction

Implementing predictive models offers numerous advantages, including:

- Cost Savings: Reduce unplanned downtime and repair expenses.

- Safety Enhancement: Prevent catastrophic failures.

- Resource Optimization: Allocate maintenance resources efficiently.

(cost efficiency, safety measures, resource management)

Implementing Predictive Models in Maintenance

To integrate corrosion prediction into your maintenance strategy, follow these steps:

- Data Collection: Gather historical and real-time corrosion data.

- Model Selection: Choose a model suited to your industry and assets.

- Training & Validation: Test the model using historical data.

- Deployment: Implement the model in your maintenance workflow.

📌 Note: Regularly update models with new data to maintain accuracy.

(maintenance strategy, data collection, model deployment)

Checklist for Predicting Corrosion Time-to-Failure

- Assess environmental and operational factors.

- Choose the right predictive model.

- Integrate IoT sensors for real-time monitoring.

- Train and validate the model regularly.

- Schedule maintenance based on predictions.

(predictive maintenance checklist, corrosion monitoring, model validation)

What is corrosion time-to-failure?

+Corrosion time-to-failure is the estimated period before a material or structure fails due to corrosion, helping in proactive maintenance planning.

How do predictive models improve maintenance?

+Predictive models analyze data to forecast failures, reducing downtime, repair costs, and safety risks.

What industries benefit most from corrosion prediction?

+Industries like oil and gas, construction, and manufacturing benefit significantly due to their reliance on metal infrastructure.

Predicting corrosion time-to-failure is no longer a luxury but a necessity for modern industries. By leveraging advanced models and technologies, businesses can ensure asset longevity, reduce costs, and enhance safety. Start implementing these strategies today to stay ahead of corrosion-related challenges. (corrosion management, predictive analytics, asset integrity)