Energy-Absorbing Polyurea Foams: Innovations in Impact Protection

<!DOCTYPE html>

In today’s fast-paced world, safety and protection are paramount across industries, from automotive to sports and construction. One groundbreaking innovation that’s transforming impact protection is energy-absorbing polyurea foams. These advanced materials are designed to dissipate energy efficiently, reducing the risk of injury and damage in high-impact scenarios. Whether you’re an engineer, athlete, or safety enthusiast, understanding the capabilities of polyurea foams can open doors to safer, more durable solutions. (impact protection, polyurea foams, energy absorption)

What Are Energy-Absorbing Polyurea Foams?

Polyurea foams are a class of elastomeric materials known for their exceptional durability, flexibility, and energy-absorbing properties. Unlike traditional foams, polyurea foams are engineered to withstand extreme conditions, including high impacts, temperature fluctuations, and chemical exposure. Their unique molecular structure allows them to deform and recover rapidly, making them ideal for applications where safety is critical. (polyurea technology, elastomeric materials, impact resistance)

Key Applications of Polyurea Foams in Impact Protection

Automotive Safety

In the automotive industry, polyurea foams are revolutionizing safety features. They are used in bumpers, interior padding, and crash zones to absorb and dissipate energy during collisions, significantly reducing the risk of injury to passengers. (automotive safety, crash protection, vehicle impact)

Sports Equipment

Athletes rely on protective gear to minimize injury risks. Polyurea foams are integrated into helmets, pads, and footwear, providing superior impact absorption without compromising comfort or performance. (sports safety, protective gear, athletic equipment)

Construction and Industrial Use

In construction and industrial settings, polyurea foams are used for fall protection systems, machinery cushioning, and structural reinforcement. Their ability to absorb energy makes them invaluable in preventing accidents and equipment damage. (construction safety, industrial protection, fall protection)

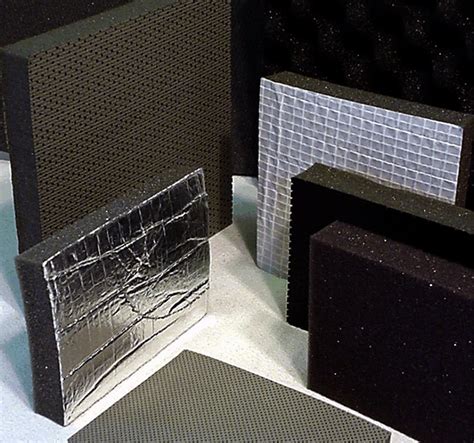

Advantages of Polyurea Foams Over Traditional Materials

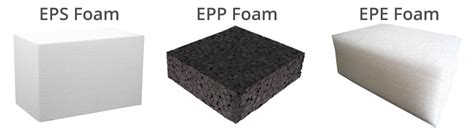

- Superior Energy Absorption: Polyurea foams outperform traditional materials like EPS and polyurethane in impact resistance.

- Durability: Resistant to wear, tear, and environmental factors, ensuring long-term performance.

- Lightweight: Offers robust protection without adding significant weight, ideal for portable applications.

- Customizable: Can be tailored to meet specific density, flexibility, and thickness requirements.

(material comparison, foam durability, lightweight protection)

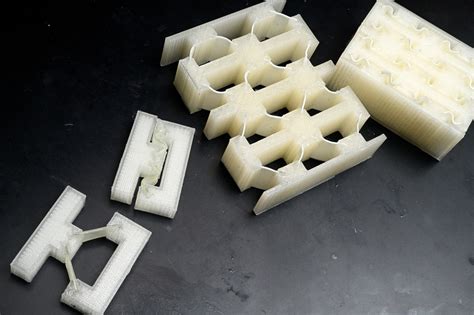

Innovations Driving the Future of Polyurea Foams

Recent advancements in polyurea technology are pushing the boundaries of what’s possible. Researchers are developing self-healing polyurea foams that can repair minor damages autonomously, extending their lifespan. Additionally, nano-enhanced formulations are improving energy absorption efficiency, making them even more effective in high-impact scenarios. (self-healing materials, nanotechnology, foam innovations)

💡 Note: When selecting polyurea foams for specific applications, consider factors like density, flexibility, and environmental exposure to ensure optimal performance.

How to Choose the Right Polyurea Foam for Your Needs

Selecting the appropriate polyurea foam depends on the application’s requirements. Here’s a quick checklist:

- Determine the level of impact protection needed.

- Assess environmental conditions (temperature, moisture, chemicals).

- Consider weight and space constraints.

- Evaluate cost versus performance benefits.

(foam selection, application requirements, performance evaluation)

Energy-absorbing polyurea foams are redefining safety standards across industries. Their unparalleled ability to dissipate energy, coupled with durability and versatility, makes them a top choice for impact protection. As innovations continue to emerge, we can expect even more advanced applications, ensuring safer environments for everyone. Whether you’re designing a new product or upgrading existing safety measures, polyurea foams offer a reliable solution to meet your needs. (safety innovations, polyurea applications, future of protection)

What makes polyurea foams better than traditional foams?

+Polyurea foams offer superior energy absorption, durability, and resistance to environmental factors compared to traditional foams like EPS and polyurethane.

Can polyurea foams be used in extreme temperatures?

+Yes, polyurea foams are highly resistant to temperature fluctuations, making them suitable for both hot and cold environments.

Are polyurea foams eco-friendly?

+While polyurea foams are durable and long-lasting, their environmental impact depends on the manufacturing process. Some formulations are being developed with sustainability in mind.