Maximizing Producto F Focus Production: A Comprehensive Guide

Maximizing Producto F Focus Production: A Comprehensive Guide

In today’s competitive market, maximizing Producto F focus production is essential for businesses aiming to stay ahead. Whether you’re a manufacturer, distributor, or retailer, understanding how to optimize production processes can significantly impact your bottom line. This guide provides actionable insights, strategies, and best practices to enhance efficiency, reduce costs, and improve product quality. From streamlining workflows to leveraging technology, we’ll cover everything you need to know to maximize your Producto F focus production. (Productivity Tips, Manufacturing Efficiency, Quality Control)

Understanding Producto F Focus Production

Before diving into optimization strategies, it’s crucial to understand what Producto F focus production entails. This term refers to the specialized manufacturing process of Producto F, a high-demand item in various industries. Efficient production requires a balance of precision, resource management, and scalability. (Manufacturing Process, Resource Management, Scalability)

Key Components of Producto F Production

- Raw Material Sourcing: High-quality materials are the foundation of superior Producto F.

- Machinery and Equipment: Advanced tools ensure precision and speed.

- Workforce Training: Skilled labor minimizes errors and maximizes output.

- Quality Assurance: Rigorous checks maintain product standards.

📌 Note: Regularly audit your supply chain to ensure consistent raw material quality.

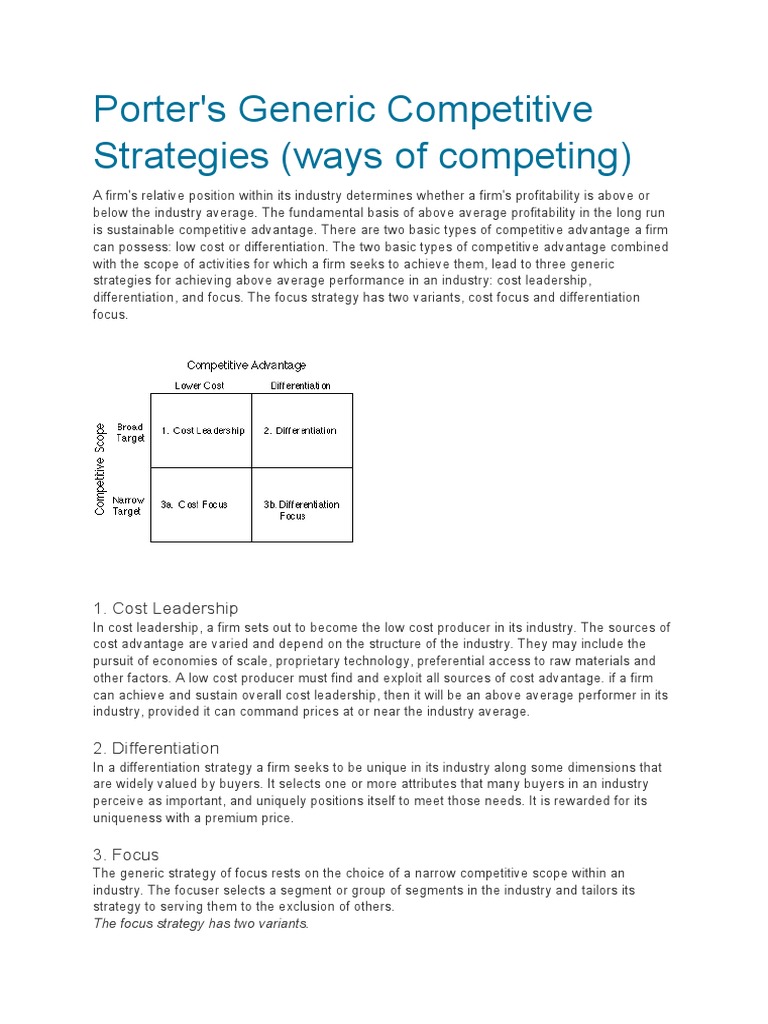

Strategies to Maximize Producto F Focus Production

1. Streamline Workflows

Efficient workflows are the backbone of maximizing Producto F focus production. Implement lean manufacturing principles to eliminate waste and reduce bottlenecks. Use tools like Kanban boards or ERP systems to visualize and manage processes. (Lean Manufacturing, Workflow Optimization, ERP Systems)

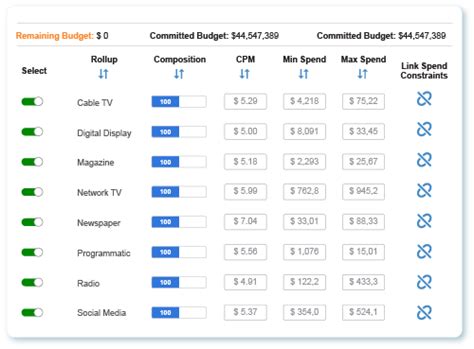

2. Invest in Technology

Automation and AI can revolutionize Producto F production. Robotic arms, IoT sensors, and predictive analytics enhance precision and reduce downtime. For example, IoT sensors monitor machine health, preventing unexpected breakdowns. (Automation, IoT, Predictive Analytics)

| Technology | Benefit |

|---|---|

| Robotic Arms | Increases speed and accuracy |

| IoT Sensors | Monitors machine performance |

3. Train and Empower Your Workforce

A skilled workforce is critical for maximizing Producto F focus production. Provide regular training on new technologies and safety protocols. Empower employees to suggest process improvements, fostering a culture of innovation. (Employee Training, Workforce Empowerment, Safety Protocols)

📌 Note: Cross-training employees can improve flexibility and cover staffing gaps.

Quality Control and Assurance

Maintaining high-quality standards is non-negotiable in Producto F production. Implement ISO certifications and conduct regular audits to ensure compliance. Use statistical process control (SPC) to monitor production in real-time. (Quality Control, ISO Certification, Statistical Process Control)

Checklist for Quality Assurance

- Inspect Raw Materials: Verify quality before production.

- Monitor Production: Use SPC tools to detect anomalies.

- Test Final Products: Ensure they meet specifications.

- Document Processes: Maintain records for traceability.

Cost Management in Producto F Production

Reducing costs without compromising quality is a delicate balance. Negotiate bulk deals with suppliers, optimize energy usage, and minimize waste. Regularly review production metrics to identify cost-saving opportunities. (Cost Management, Supplier Negotiation, Energy Efficiency)

Cost-Saving Tips

- Bulk Purchasing: Reduce material costs.

- Energy Audits: Identify inefficiencies in power usage.

- Waste Reduction: Implement recycling programs.

Scaling Producto F Production

As demand grows, scaling production becomes essential. Invest in modular equipment that can adapt to increased output. Expand your workforce strategically, focusing on skilled labor. Ensure your supply chain can handle higher volumes without disruptions. (Production Scaling, Modular Equipment, Supply Chain Management)

📌 Note: Test scaling strategies in phases to avoid overwhelming your operations.

Final Thoughts

Maximizing Producto F focus production requires a holistic approach, combining efficient workflows, technology, and a skilled workforce. By prioritizing quality, managing costs, and planning for scalability, businesses can achieve sustainable growth. Implement the strategies outlined in this guide to stay competitive and meet market demands effectively. (Sustainable Growth, Competitive Advantage, Market Demand)

What is Producto F focus production?

+Producto F focus production refers to the specialized manufacturing process of Producto F, emphasizing efficiency, quality, and scalability.

How can technology improve Producto F production?

+Technology like automation, IoT sensors, and AI enhances precision, reduces downtime, and optimizes workflows in Producto F production.

Why is quality control important in Producto F production?

+Quality control ensures Producto F meets industry standards, maintains customer trust, and avoids costly recalls or reworks.