Remote Center STL: Precision Engineering Simplified

<!DOCTYPE html>

In the world of precision engineering, achieving accuracy and efficiency is paramount. One innovative solution that stands out is the Remote Center STL. This technology simplifies complex engineering tasks, making it an essential tool for professionals in various industries. Whether you’re looking to enhance your manufacturing processes or streamline design workflows, understanding Remote Center STL can be a game-changer. Let’s dive into how this technology works and why it’s becoming a cornerstone in precision engineering, (precision engineering, manufacturing technology, design workflows).

What is Remote Center STL?

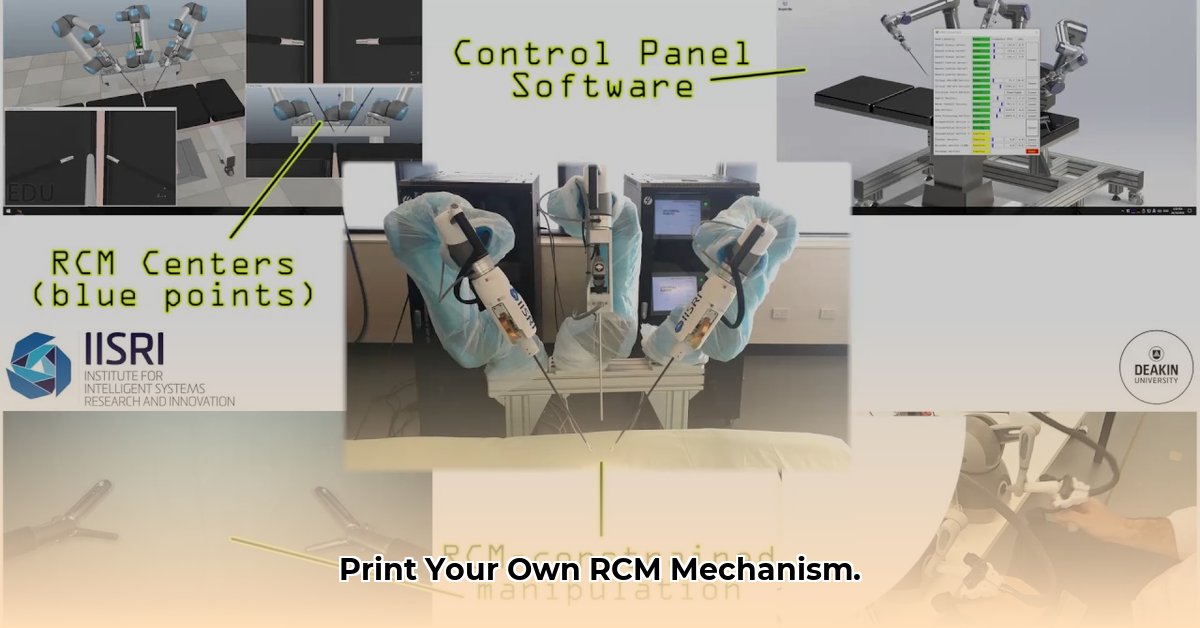

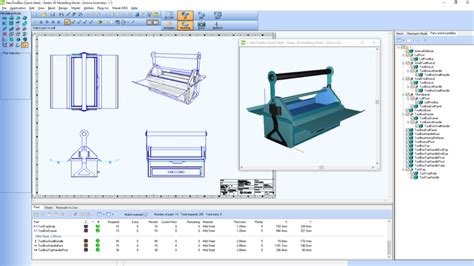

Remote Center STL refers to a specialized mechanism used in engineering and manufacturing to achieve precise rotational movements. It is particularly crucial in applications requiring high accuracy, such as CNC machining, robotics, and 3D printing. The “STL” stands for Stereolithography File Format, a standard file type used in 3D printing and CAD software, (CNC machining, robotics, 3D printing, CAD software).

How Does Remote Center STL Work?

The Remote Center STL operates by allowing rotational axes to pivot around a fixed point, known as the remote center. This ensures that movements are both precise and repeatable, minimizing errors in complex operations. Here’s a breakdown of its functionality:

- Fixed Pivot Point: The remote center acts as the anchor for rotational movements.

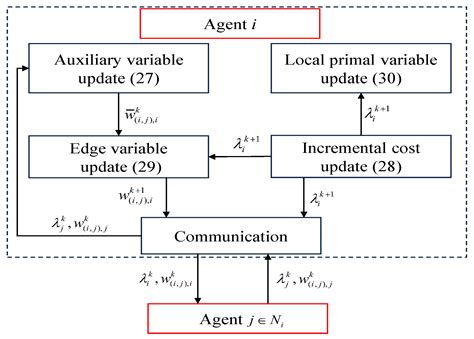

- Precision Control: Advanced algorithms and sensors maintain accuracy during operation.

- Versatility: Applicable in various industries, from aerospace to automotive, (aerospace engineering, automotive manufacturing, precision control).

Benefits of Using Remote Center STL

Incorporating Remote Center STL into your workflow offers numerous advantages. Below are some key benefits:

- Enhanced Accuracy: Reduces errors in rotational movements, ensuring high-quality outputs.

- Increased Efficiency: Streamlines processes, saving time and resources.

- Scalability: Adaptable to both small-scale projects and large industrial applications, (enhanced accuracy, increased efficiency, scalability in engineering).

Applications of Remote Center STL

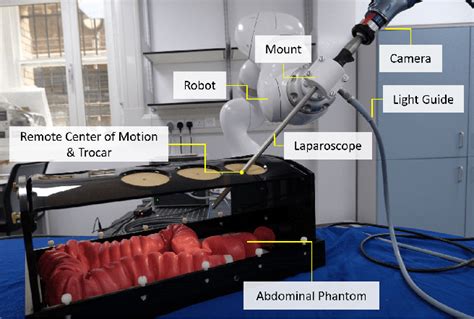

The versatility of Remote Center STL makes it suitable for a wide range of applications. Here are some notable examples:

| Industry | Application |

|---|---|

| Aerospace | Precision assembly of aircraft components |

| Automotive | Manufacturing of engine parts |

| Healthcare | Production of medical devices |

📌 Note: When implementing Remote Center STL, ensure compatibility with your existing systems for optimal performance, (system compatibility, optimal performance, implementation tips).

Getting Started with Remote Center STL

If you’re ready to integrate Remote Center STL into your operations, follow these steps:

- Assess Your Needs: Identify specific applications where precision is critical.

- Choose the Right System: Select a Remote Center STL solution tailored to your industry.

- Train Your Team: Ensure operators are familiar with the technology for seamless integration, (assessing needs, choosing systems, team training).

Remote Center STL is revolutionizing precision engineering by offering unparalleled accuracy and efficiency. Whether you’re in aerospace, automotive, or healthcare, this technology can significantly enhance your operations. By understanding its functionality, benefits, and applications, you can make informed decisions to elevate your engineering processes. Embrace Remote Center STL and take your precision engineering to the next level, (revolutionizing precision engineering, enhancing operations, informed decisions).

What industries benefit most from Remote Center STL?

+Industries such as aerospace, automotive, and healthcare benefit significantly due to the high precision requirements in their manufacturing processes, (aerospace, automotive, healthcare).

Can Remote Center STL be integrated with existing CNC machines?

+Yes, Remote Center STL can be integrated with most CNC machines, provided they support the necessary rotational movements and software compatibility, (CNC machines, software compatibility, integration tips).

How does Remote Center STL improve efficiency in manufacturing?

+By ensuring precise and repeatable movements, Remote Center STL reduces errors and downtime, leading to faster production cycles and cost savings, (improving efficiency, reducing errors, cost savings).