6000 Series Aluminum in Aerospace: Key Applications Explained

The aerospace industry demands materials that combine strength, lightweight properties, and corrosion resistance. Among the many alloys used, 6000 series aluminum stands out as a versatile and reliable choice. This series, known for its silicon and magnesium composition, offers exceptional formability and weldability, making it ideal for various aerospace applications. From aircraft structures to interior components, 6000 series aluminum plays a pivotal role in modern aviation. In this post, we’ll explore its key applications, benefits, and why it’s a preferred material in aerospace engineering,aluminum alloys,aerospace materials,lightweight metals.

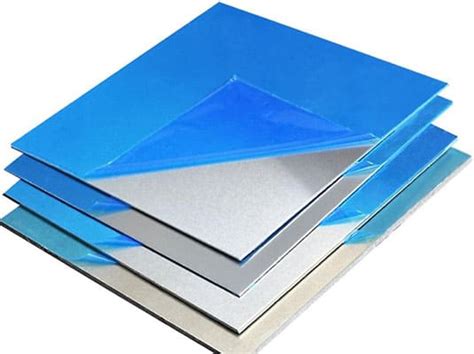

What is 6000 Series Aluminum?

The 6000 series aluminum is an alloy primarily composed of aluminum, silicon, and magnesium. This combination provides excellent strength-to-weight ratios, making it a top choice for industries where weight reduction is critical. Its ability to be heat-treated further enhances its mechanical properties, ensuring durability in demanding environments,aluminum properties,material science,aerospace engineering.

Key Applications in Aerospace

Aircraft Structural Components

One of the most significant uses of 6000 series aluminum is in aircraft structural components. Its high strength and lightweight nature make it perfect for wings, fuselage panels, and other load-bearing parts. This reduces the overall weight of the aircraft, improving fuel efficiency and performance,aircraft manufacturing,structural integrity,fuel efficiency.

Interior Cabin Elements

Beyond structural applications, 6000 series aluminum is widely used in aircraft interiors. Seats, overhead bins, and partitions benefit from its corrosion resistance and ease of fabrication. Its ability to withstand harsh cabin conditions ensures longevity and safety,aircraft interiors,passenger comfort,material durability.

Aerospace Fasteners

Fasteners like bolts, screws, and rivets are critical in aerospace assembly. The 6000 series aluminum is often used here due to its excellent machinability and resistance to stress corrosion cracking. This ensures secure and reliable connections in aircraft components,aerospace fasteners,machinability,corrosion resistance.

| Property | 6000 Series Aluminum | 7000 Series Aluminum | 2000 Series Aluminum |

|---|---|---|---|

| Strength | High | Very High | Moderate |

| Formability | Excellent | Good | Fair |

| Corrosion Resistance | Good | Moderate | High |

Benefits of 6000 Series Aluminum in Aerospace

- Lightweight: Reduces aircraft weight, enhancing fuel efficiency.

- Corrosion Resistance: Ensures longevity in harsh environments.

- Formability: Allows for complex shapes and designs.

- Cost-Effective: Offers a balance between performance and affordability.

📌 Note: While 6000 series aluminum is highly versatile, it may not be suitable for extremely high-temperature applications. Always consult material specifications for specific use cases.

In summary, 6000 series aluminum is a cornerstone material in aerospace engineering, offering a unique blend of strength, lightweight properties, and corrosion resistance. Its applications span from structural components to interior elements, making it indispensable in modern aircraft design. By understanding its benefits and limitations, engineers can leverage this alloy to create safer, more efficient, and cost-effective aerospace solutions,aerospace innovation,material selection,engineering excellence.

What makes 6000 series aluminum ideal for aerospace?

+

Its lightweight nature, corrosion resistance, and excellent formability make it perfect for aerospace applications.

Can 6000 series aluminum be used in high-temperature environments?

+

While it’s durable, it’s not recommended for extremely high-temperature applications. Other alloys like the 7000 series are more suitable.

How does 6000 series aluminum compare to other alloys?

+

It offers a balance of strength, formability, and cost-effectiveness, making it a preferred choice over higher-strength but less formable alloys.