Punch Formed Bellows: Ultimate Flexibility in Industrial Applications.

In the world of industrial applications, flexibility and durability are key. One component that embodies these qualities is the punch formed bellows. These innovative devices are designed to provide ultimate flexibility while maintaining structural integrity, making them indispensable in various industries. Whether you’re looking to understand their functionality or considering their implementation, this post will guide you through everything you need to know about punch formed bellows.

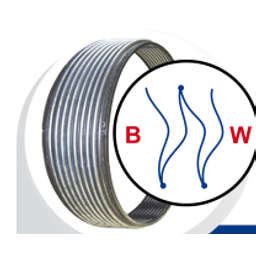

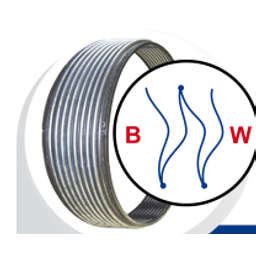

What Are Punch Formed Bellows?

Punch formed bellows are flexible, accordion-like structures created through a precision manufacturing process. They are typically made from metal and are used to protect, guide, or compensate for movement in mechanical systems. Their unique design allows them to expand and contract, providing exceptional flexibility without compromising strength.

💡 Note: Punch formed bellows are ideal for applications requiring both movement and protection, such as in robotics, aerospace, and automotive industries.

Key Features of Punch Formed Bellows

- Flexibility: Allows for axial, lateral, and angular movement.

- Durability: Resistant to harsh environments, including extreme temperatures and chemicals.

- Precision: Manufactured with tight tolerances for optimal performance.

- Customization: Available in various sizes, materials, and configurations to meet specific needs.

Applications of Punch Formed Bellows

Punch formed bellows are versatile and find applications across multiple industries:

- Automotive: Used in exhaust systems and suspension components.

- Aerospace: Essential for aircraft actuators and fuel systems.

- Robotics: Provides flexibility in robotic joints and arms.

- Industrial Machinery: Protects sensitive components from dust and debris.

| Industry | Application |

|---|---|

| Automotive | Exhaust systems, suspension |

| Aerospace | Actuators, fuel systems |

| Robotics | Joints, arms |

Benefits of Using Punch Formed Bellows

- Enhanced Performance: Improves system efficiency by accommodating movement.

- Longevity: Reduces wear and tear on connected components.

- Cost-Effective: Minimizes maintenance and replacement costs.

- Versatility: Suitable for a wide range of industrial applications.

How to Choose the Right Punch Formed Bellows

Selecting the appropriate punch formed bellows involves considering several factors:

- Material: Choose based on the operating environment (e.g., stainless steel for corrosion resistance).

- Size: Ensure compatibility with your system’s dimensions.

- Movement Requirements: Assess the need for axial, lateral, or angular flexibility.

- Load Capacity: Verify that the bellows can handle the expected stress.

⚠️ Note: Always consult with a manufacturer to ensure the bellows meet your specific application requirements.

Final Thoughts

Punch formed bellows offer unparalleled flexibility and durability, making them a cornerstone in modern industrial applications. Whether you’re in automotive, aerospace, or robotics, these components can significantly enhance the performance and longevity of your systems. By understanding their features, applications, and selection criteria, you can make informed decisions to optimize your operations.

What materials are punch formed bellows made of?

+Punch formed bellows are typically made from metals like stainless steel, brass, or aluminum, chosen for their durability and resistance to environmental factors.

Can punch formed bellows handle high temperatures?

+Yes, they are designed to withstand extreme temperatures, making them suitable for high-heat applications in industries like aerospace and automotive.

How do I determine the right size of punch formed bellows?

+Measure the required stroke length, installation space, and movement type (axial, lateral, angular) to select the appropriate size.

metal bellows,industrial components,flexible bellows,mechanical systems,punch formed bellows applications